Grits

The range of Colorobbia grits has been developed with the aim of satisfying the most ambitious expectations. In addition to offering a vast selection of ceramic effects, the grits are also available in a broad range of grain sizes, thus allowing them to be used with all existing application systems, both wet and dry.

This series is represented by glossy transparent grits. These have been designed in such a way that they can be used either singularly or in combination, allowing excellent flexibility of use both in terms of firing cycles and body types. Their high transparency allows the excellent development of digital colours, even when used in high thickness, for example in the case of lapped products where they generate extremely compact glass. In larger grain sizes, they can be used as specks or to create a “sugar” type effect.

This series is represented by a hyperwhite grit formulated for compatibility with all other grits in the range and therefore to be used in combination with them as specks. It can also be used on its own as decoration (white grain pattern) or mixed in with glazes, insofar as due to its extreme whiteness, it has a fusibility allowing it to perfectly melt without creating a relief effect and unpleasant tactile sensation.

This series is represented by matt transparent grits with high resistance to light-foot traffic. This is the series with the highest number of codes. This is due to a careful study of their chemical characteristics performed by Colorobbia in an effort to identify the best way to combine their technical properties with the soft or non-slip matt surfaces that need to be created, in accordance with the different temperatures of use. Moreover, as can be inferred from their physical characteristics listed in the catalogue, they can be used in a broad range of firing temperatures (from wall tiles to floor tiles) and easily adapt to the majority of ceramic supports.

They are transparent grits and this translates into excellent colour development; normally, in the case of lapped tile production, they create – either on their own or with glossy grits – very transparent and compact glass.

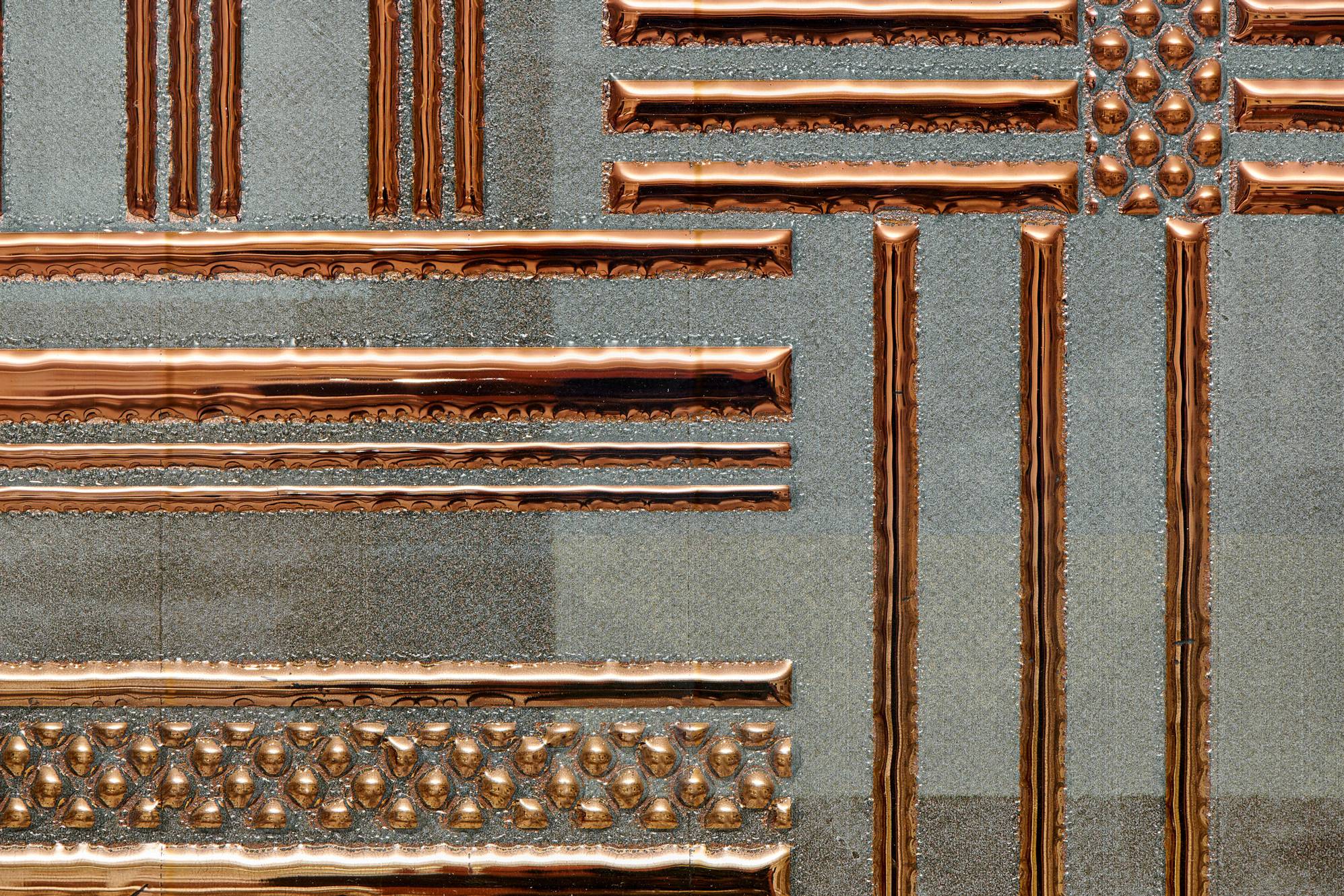

The last of the grit series, but no less important. This series is represented by grits with a shiny or metallic effect. It’s worth noting that despite being special effect grits, their resistance to chemical attacks is guaranteed in our standard firing conditions (1205 for 50 minutes). They can be used either on their own or mixed with other grits in the range to create a speckled effect. For this reason they are not supplied in all grain sizes but only those allowing use with dry application or as a speckled effect.

Colorobbia: all the solutions

The Colorobbia Group operates worldwide and specialises in the study, production and distribution of raw materials and semi-finished products for the ceramics and glass industry.