Glazes

The Colorobbia Group offers a broad range of compounds and glazes.

The family of Colorobbia glazes is the result of the application of its own knowledge and expertise to the composition of frits, raw materials and additives.

Colorobbia offers clients all types of engobes, glazes and protective coatings specifically trailored to suit their commercial and production needs. The entire range of products has been designed seeking to optimise compatibility between the various materials to achieve utmost performance. Colorobbia is therefore able to satisfy all client needs, both in terms of the production process and aesthetic and functional characteristics of the final product.

Colorobbia offers clients a broad range of ceramic glazes, ensuring the perfect solution for all types of technology:

- Third and fourth fire decorative processes

- Rapid double-firing

- Porous single-fired

- Single-fired

- Glazed porcelain stoneware

- Technical porcelain stoneware

For each of these technologies, Colorobbia presents the following families:

Engobes are a combination of frits and raw materials, which act as an interface between the support and the glaze. The engobes thus facilitate improved coupling between the support and glaze, while also satisfying the desired technical characteristics: curvature, fusion, opacity, water flow, etc.

For each type of production technology, Colorobbia proposes a broad range of engobes and single glazes able to satisfy the various technical requirements expressed by clients.

The range of engobes can be broken down into different types:

- Custom engobes for each production technology (double-firing, porous single-fired, stoneware and porcelain stoneware)

- Hyperwhite engobes

- High coefficient engobes

- Stain-resistant engobes with high opacity and whiteness

- Engobes for construction materials (tiles, bricks, exposed bricks, engobes for roof-tiles, etc…)

- Engobes for special pieces

Colorobbia proposes a complete range of glazes and protective coatings able to respond to all needs.

In particular, the range is distinguished by the following types:

- Matt glaze

- Matt transparent matt glaze

- Matt transparent soft touch glaze

- Matt opaque glaze

- Matt No-reflex glaze

- Matt glaze for polishing

- Glossy glaze

- Glossy opaque glaze

- Glossy glaze for polishing

- Glossy glaze for technical porcelain stoneware

- Transparent protective coatings

- Protective coatings with low reflectance index

- Transparent matt protective coatings

The Colorobbia range of glazes and protective coatings for polishing includes a specific series with high dilatometric coefficient of thermal expansion, a perfect solution for large formats.

Colorobbia presents a new range of glazes with different reflectance indices and surface roughness, thus making it possible to obtain:

- Technical non-slip surfaces (from R9 to R13) for both interiors and exteriors. These glazes allow surface structures to be designed according to the requested value (from R9 to R13), thus guaranteeing compliance with each country’s specific certification standards for flooring in public and/or private locations.

- Surfaces with high resistance to wear, suitable for intense light-foot, vehicular and goods traffic

This family of functional glazes guarantees at all times:

- Excellent development of digital inks, colours and effects.

- High resistance to stains (total cleaning).

- High chemical resistance.

Colorobbia also offers the possibility to combine glazes and protective coatings with its family of grits and micro-grits, for both wet and dry application, to obtain higher performing surfaces.

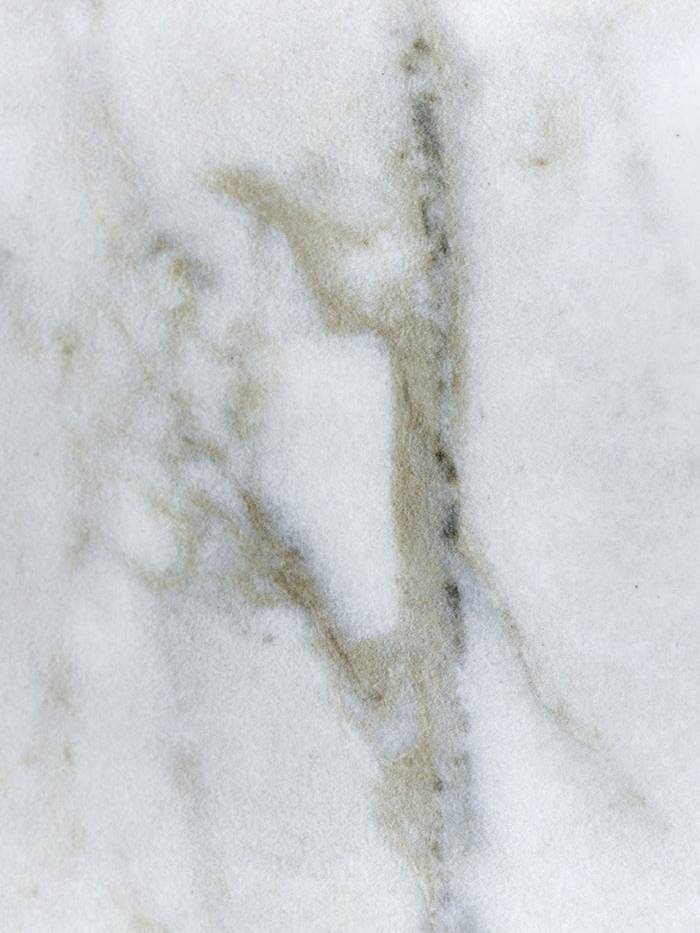

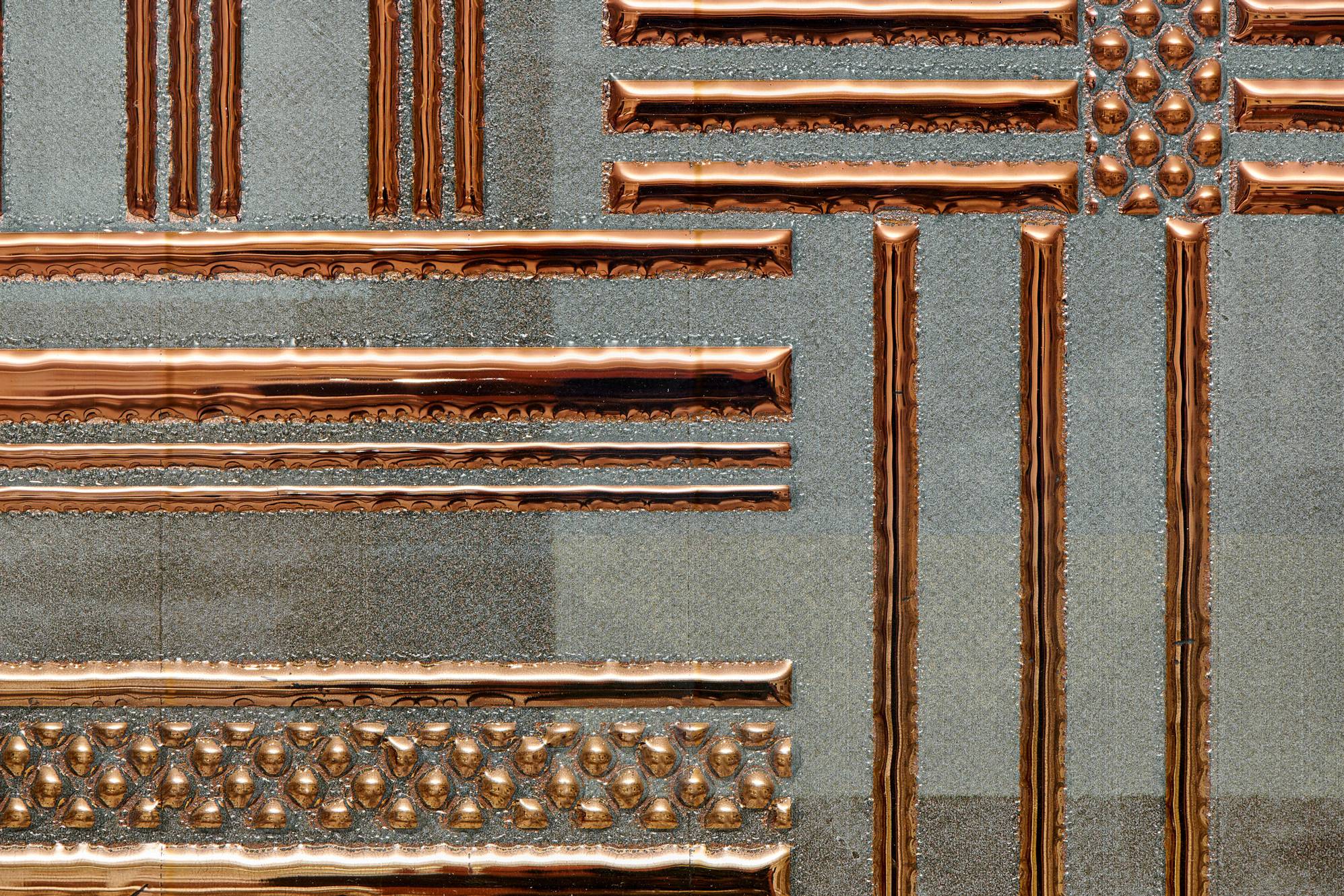

This range of glazes, which allows the creation of truly unique effects, is available in different shades and finishes:

- Shiny glazes

- Iridescent glazes

- Metallic glazes (waxy, bronze and platinum finishes)

- Coloured glazes (such as Raku)

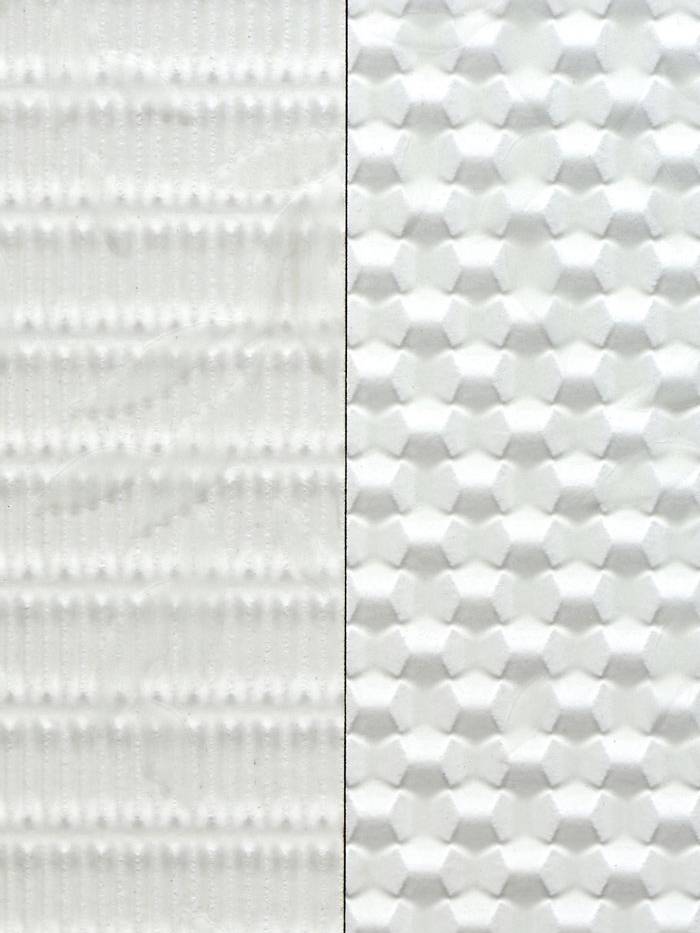

These micronized glazes are used to prepare inks, with higher or lower viscosity carriers depending on the printing process, through flat, rotary or roller screen printing with relief or rotogravure.

The micronized glazes can be coloured by adding different percentages of dispersible micronized pigments in the wet and/or dry mixing processes.

Spray glazes are granules of variable composition with more or less rounded forms and sufficient hardness for handling, use and transport. They are manufactured according to standardised grain sizes for use during the pre- and post-pressing stages.

These materials allow the base substrates to be enriched prior to the digital decoration of the product. This category also includes a version with finer grain size, particularly useful for decorative surface finishes.

Glazes for structures are materials formed into different shapes (lamellar or agglomerate, irregular, flakes, etc…), allowing the creation of unique visual effects for use in niche products with high added value.

Colorobbia: all the solutions

The Colorobbia Group operates worldwide and specialises in the study, production and distribution of raw materials and semi-finished products for the ceramics and glass industry.