Grinding Media and Technical Ceramics

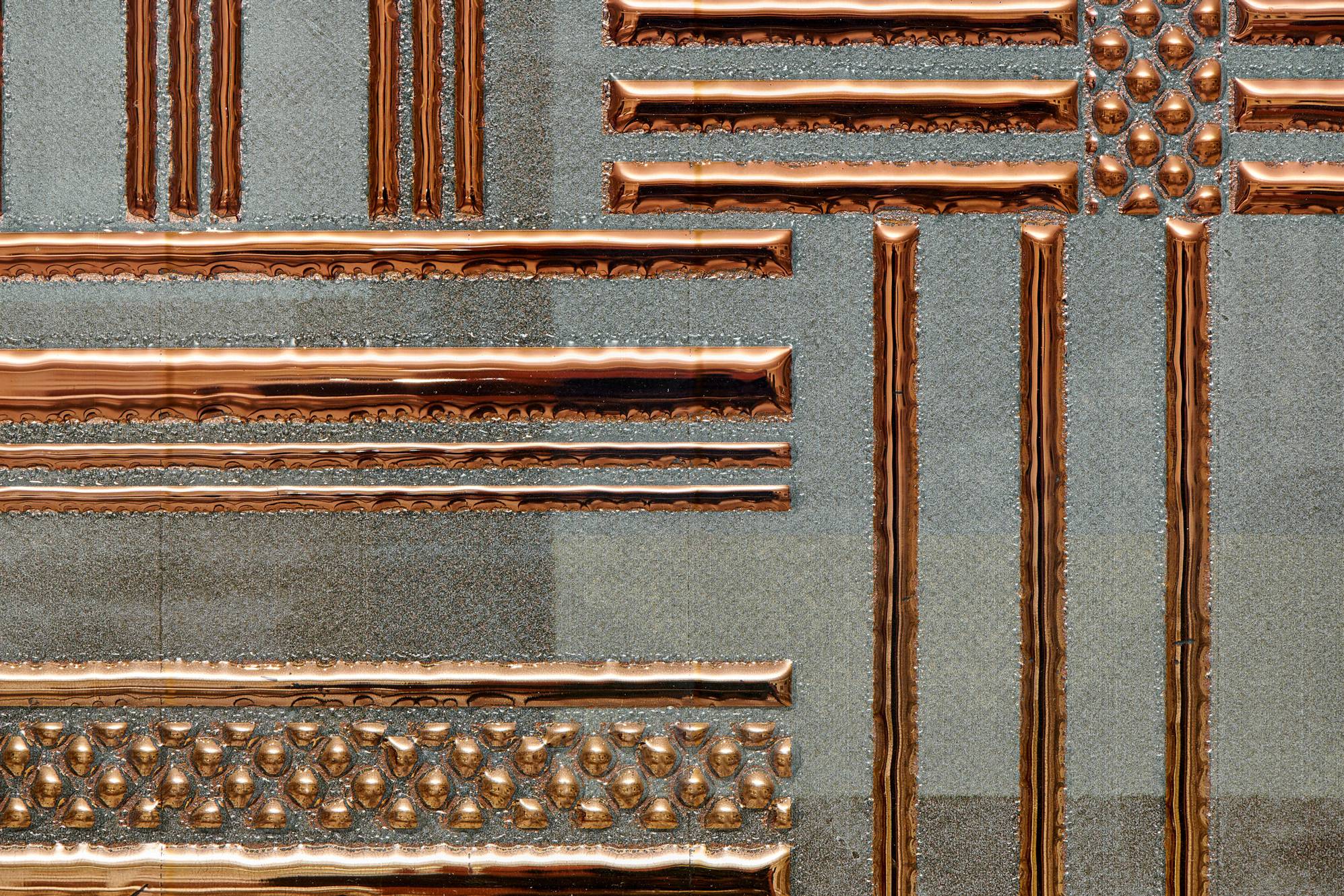

The company has always played a key role in the ceramic body, glaze and mineral grinding sector, distinguished by its innovation and advanced technology thanks to the development of grinding charges that have revolutionised the work of grinding mills, optimising their performance.

Alubit Leonardo, a global leader in the production of high-density alumina grinding media, has forever played a leading role in the ceramic body, glaze, mineral and precious metal grinding sector, distinguished by the quality of its production and personalised technical assistance. Thanks to the development of high-performing grinding charges specific to each single field of application, we have contributed to improving the performance of production plants, whether discontinuous or continuous, significantly reducing the specific consumption of grinding machines.

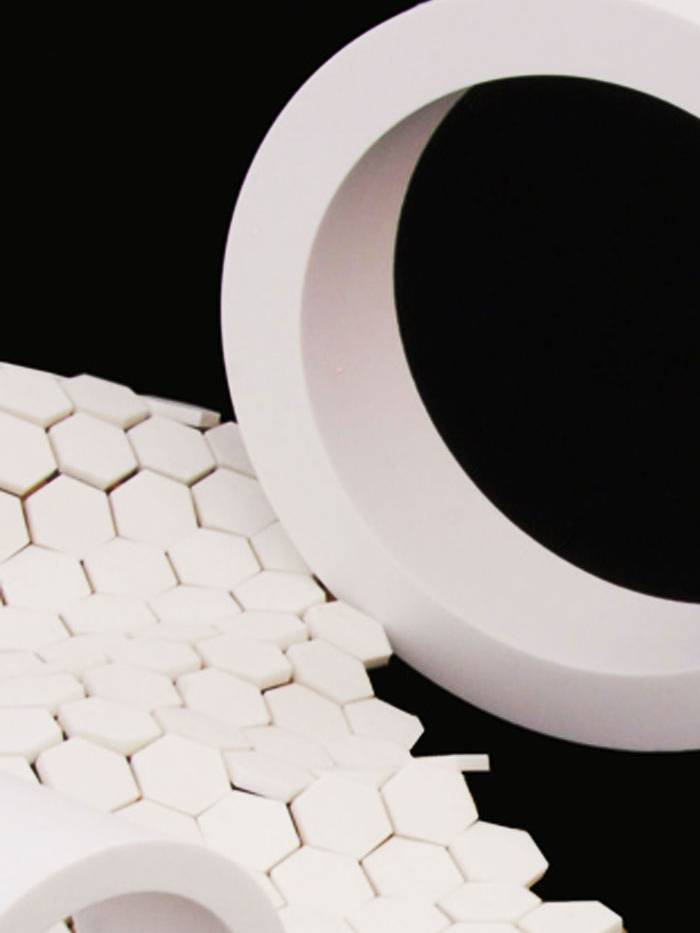

“Sphericity, density, absence of open pores”, these are the most important technical characteristics for the use of Supporbit balls as a catalyst support in petrochemical plants, gas treatments and for the production of fertilisers.

Duralbit linings, installed in highly abrasive and/or corrosive work environments, offer efficient anti-wear solutions, considerably reducing the need for technical intervention and relative maintenance costs.

A benchmark company on a global scale for the production of micronized zirconium. Thanks to their high-level whiteness and coverage, Zircobit products, with various grinding fineness, are used in the production of ceramic grits and glazes for ceramics and sanitaryware, as bleaching agents in porcelain stoneware bodies and to produce refractories in general.

Colorobbia: all the solutions

The Colorobbia Group operates worldwide and specialises in the study, production and distribution of raw materials and semi-finished products for the ceramics and glass industry.